MANUFACTURING TECHNIQUES FOR ACHIEVING HIGHER PRODUCTIVITY (HIGHER SPEED FABRICATION)

One of the primary objectives of the Hub is the integration of current AM technology with empirical evidence to drive and support new manufacturing techniques for the aerospace and biomedical industries.

PROCESSING PARAMETERS FOR BIOMEDICAL COMPONENTS

Develop processing parameters to enable higher speed and lower cost for biomedical component production.

Hub research has led to the optimisation of the processing parameters for AlSi10Mg, AS7G06 Hastelloy X and Ti64. Selective Laser Melting (SLM) build strategies have been developed for aerospace components of different sizes and types.

The Hub has also been able to demonstrate strategies for achieving higher productivity, particularly for some larger components, on the Concept Laser machine at Monash Centre for Additive Manufacturing (MCAM).

PROCESSING PARAMETERS FOR AEROSPACE COMPONENTS

Develop processing parameters to enable higher speed and lower cost for aerospace component production.

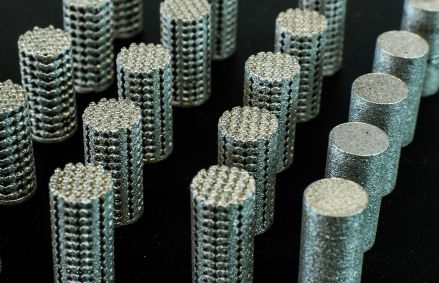

Hub research on Ti64 has led to a thorough understanding of how SLM processing parameters and component designs can be altered to enable higher speed fabrication of lattice structures that are optimised for implants (including cell attachment and Young’s modulus considerations).

The Hub has conducted comparisons between microstructures and properties resulting from SLM strategies optimised for high productivity and for lower productivity. Based on these comparisons, post heat treatments and hot isostatic press (HIP) treatments have been optimised, allowing for productivity improvements without a loss in properties.